Call Today 01430 449440

Energy modelling for horticulture: How we use it to deliver staggering savings

By Charlotte Penn, Energy Analyst & Business Development Manager

Identifying solutions that can achieve significant energy savings is an increasingly popular way for food producers to drive down growing costs.

At CambridgeHOK, we have devised an ‘energy modelling’ consultation specifically for the horticulture sector, which looks at cropping profiles alongside energy demands, enabling us to work with the grower and develop a grow strategy that offers an optimum yield-energy ratio.

Rather than adopt a one-size fits-all approach, we are led by growers and work together to analyze every aspect which impacts on planting and fruiting.

For some of the biggest businesses we work in partnership with, this has delivered six and seven-figure savings over the course of a year.

If you’d like to enjoy similar savings, please call 01430 449440 – or read on to find out more about our energy modelling process.

The mains areas for analysis

In a recent energy review conducted for a significant commercial glasshouse grower looking to expand, we evaluated their current energy matrix and proposed all the options available for reducing CO2 and energy savings.

As with all our Energy analysis, we looked at three main areas:

1. Existing Consumption

We compared their existing on-site heat and electricity demand enabling us to analyse potential technologies which could be implemented and rule out those which would offer little savings.

2. Cropping Profile

We evaluated existing cropping profiles and explored the benefits of splitting the glasshouse into sections, staggering the cropping profile to allow year-round production whilst reducing peak demands and pressure on the grid or alternative technologies. In addition, we looked at optimising energy and reducing set daytime temperatures (that rely on fuels) and maximising solar gain. All of this not only helps smooth peaks in energy demand, and reduces overall demand by around 30 per cent, but also reduces infrastructure costs.

3. Predicted Energy Demands

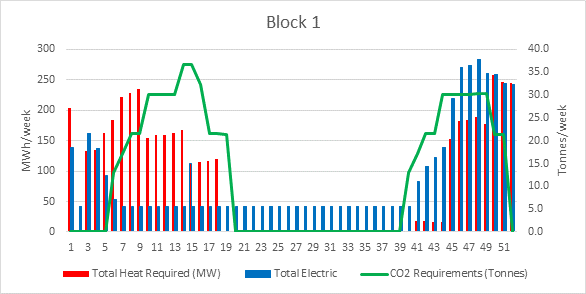

After splitting the glasshouse into blocks, we evaluated each block’s energy requirements based on their individual cropping cycle, and what future demands would look like, through expansion both with and without LED lighting. We offered a full breakdown of weekly demands down to hourly peaks and outlined how we could shift these about by amending the cropping profiles of the existing growth with future expansion. This enabled the grower to make all commercial decisions with a full perspective of growing costs.

Explaining the best energy options

Having analysed the way in which a growing site operates, the next step is to look into all the available energy options.

Below is an insight into the cost analysis we recently conducted for a grower who wanted to reduce their carbon footprint and energy costs.

Grid: To reduce carbon emissions, we recommended switching all tariffs to renewable ones, working with an energy provider who could source renewable energy or offset where it was not possible. However, in the long term this meant the grower would be constrained by grid requirements and subject to tariff changes.

Combined Heat & Power (CHP): Installing a CHP could produce all the electricity, heat and CO2 required, but they don’t always stack up financially if there is not a significant heat or CO2 demand. In this case, our calculations predicted a 7-year payback from an initial £1.1m investment.

Heat Pump: At certain times of the year, this energy method – which typically produces three units of heat to every unit of electricity put in – would lead to a heat shortfall. It would need to be used in conjunction with a CHP to meet CO2 requirements for growing. However, heat pumps are great for top-up heat where you have satisfied CO2 levels within the glasshouse but where a more renewable alternative is wanted to meet the rest of the heat demand.

Hydrogen: Whilst this could help to reduce the on-site carbon footprint, liquid CO2 would need to be sourced to balance out the hydrogen vs fossil fuel usage. Alternatively, we could look to blend green and blue hydrogen to meet CO2 but reduce the overall footprint. This was a financially-attractive option which required further exploration.

How crop cycle impacts on energy savings

As outlined above, the cropping profile has a huge impact on the energy demands for a site and therefore we always start by understanding a grower’s requirements before analysing energy solutions.

Further to the work we do within glasshouses, we can also model how a glasshouse works amongst a wider site, where growers have other ventures and see how the energy requirements and CO2 offsetting can be blended.

Taking a holistic approach to energy is a key element for growers to really understand how their horticultural decisions are impacting their running costs.

A recent project looked a breaking down the energy requirements of a significant site into 5 blocks and how we could manoeuvre the cropping cycles to not only meet the grower’s requirements but also keep demands within grid limits.

To discover if we could help you to make notable energy savings, get in touch or call 01430 449440 for an informal discussion.

Call us to speak to a member of our team or complete the enquiry form and we will get back to you

- 01430 449440

- [email protected]

- Wallingfen Park

236 Main Road

Newport, Brough

East Yorkshire

HU15 2RH